Effect of noodle material changes on composite tee pull-off forces

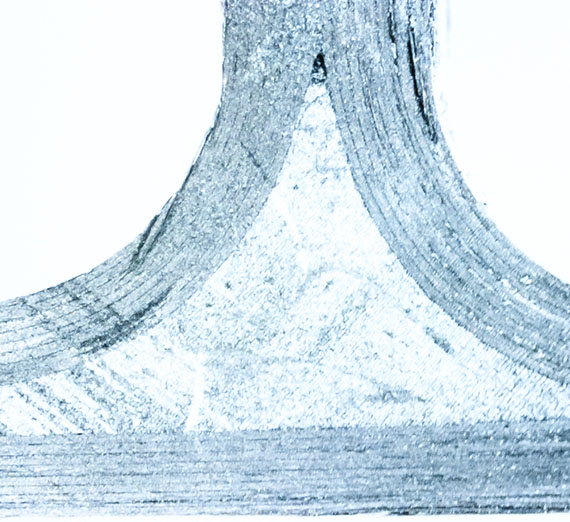

A “noodle” or deltoid shape fills the gap created when composite materials formed to a radius are brought together to for a tee intersection. This student research project investigated the use of different noodle materials and their impact on the pull-off force required to separate the vertical portion of the tee from the horizontal base.