Click on any instrument to learn more

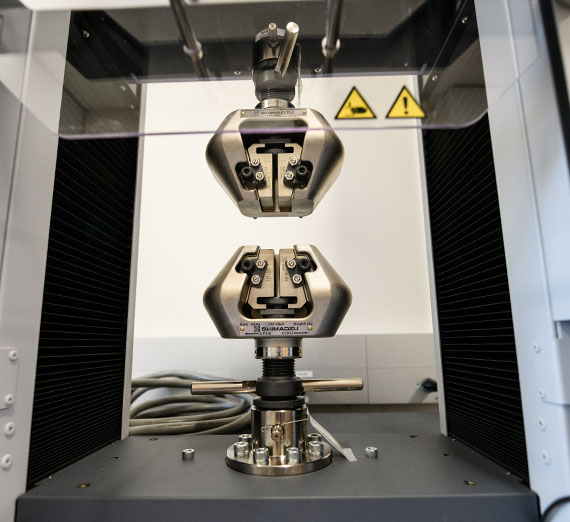

Mechanical Test Frame

Shimadzu AGS-X 50 kN

- Test samples in tension, compression, shear

- 50 kN (11,240 lb) load

- Optical extensometer to measure deformation through final fracture

- Maximum crosshead speed 1100 mm/min (3.937 in/min)

- Maximum tensile stroke 1210mm (47.64 inches)

with Optical Extensometer

- Field of view 50-500 mm (1.969-19.69 inches)

- Maximum elongation capability > 1000%

- Dynamic resolution < 2.5="" μm="" (0.00009842="" />

Mechanical extensometers are usually removed after a few percent of permanent deformation to prevent damage caused by energy release during specimen failure. A non-contact extensometer does not have this limitation, allowing the capture of strain data for the entire test. Optical extensometers also enable testing of fine, delicate specimens without unwanted influence or contact stresses as well as providing accurate measurements on low strain-to-failure samples.

Fixtures

- Tension

- Compression

- Three-point bending

- Shear properties by V-notched beam

- Combined loading compression

- Climbing drum peel

Contact Angle Goniometer

Kruss DSA25 Standard Drop Shape Analyzer

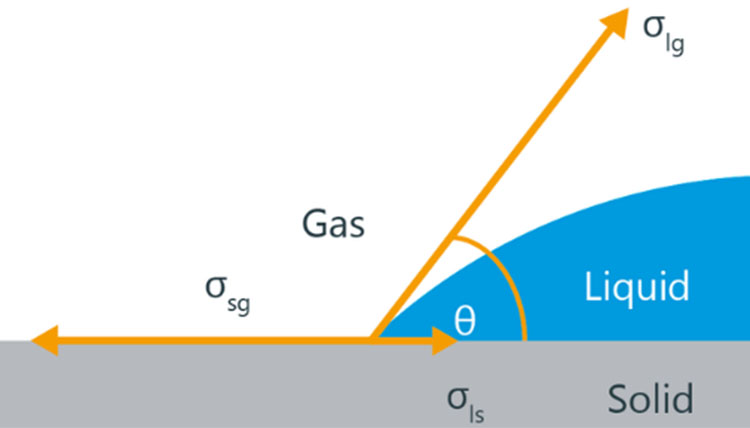

- Measures contact angle between liquid drop and solid surface.

- Enables calculation of surface energy.

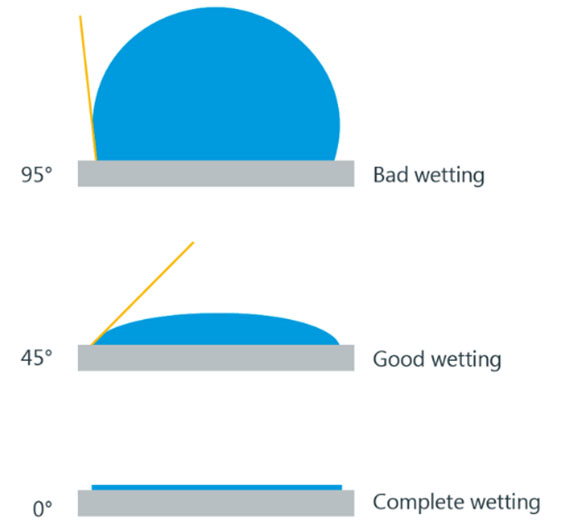

The Greek roots are gonia (angle) and metron (measure). A goniometer measures the contact angle between a liquid drop and a solid substrate. By using a series of liquids with known surface energy properties and by measuring the liquid to solid contact angle, the surface energy of the solid substrate can be determined.

Knowing the solid substrate surface energy and the surface energy properties of a candidate adhesive, we can determine whether the adhesive will “wet” the substrate and lead to good bonding. Bad wetting leads to incomplete adhesion and reduced adhesive joint strength. In other applications, bad wetting is encouraged by applying wax to a car body or Rain-X to its windshield so that rain drops will bead up.

Confocal Laser Microscope

Keyence VK-X3050

- Magnifies images up to 28800x

- Gathers surface roughness profile information

- Field of View: 11 to 7398 μm

- Interferometry Height Resolution: 1 nm

The system incorporates two light sources, a white light for gathering color and a laser source for scanning the surface of an object and collecting detailed height information. The laser scans in the XYZ directions to collect data throughout the specified range. The result is a high-resolution, large depth-of-field, color image with nanometer-level height resolution for accurate profile and roughness measurements. This equipment is able to combine a lot of the functionality of an optical microscope, the detail of a scanning electron microscope, and the profilometry of a white light interferometer while maintaining the ease-of-use of an optical microscope.

Optical Microscope

Nikon SMZ 800N

- Zoom range: 1-8x

- Ring illuminator with polarizing ability

- 10-megapixel resolution

Microhardness Tester

Shimadzu HMV-G31

Uses the Vickers microhardness technique - a pyramid-shaped indenter is pressed into the surface. The length of the diagonal indent determines the hardness value.Hardness test methods displace an indenter into a surface under a specific load. The size or depth of indentation is measured to determine hardness which correlates to sample strength.

Hardness testing is divided into two ranges: macrohardness and microhardness. Microhardness testing has lower applied loads and is typically used for smaller samples, thin specimens, or for more closely spaced test locations such as those used for determining strength drops in a heat affected zone.

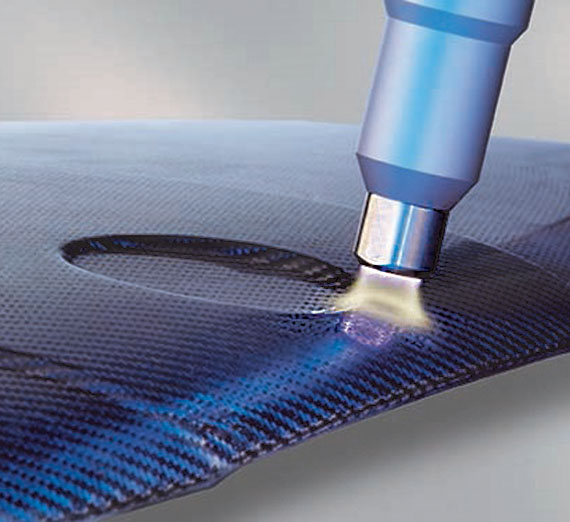

Atmospheric Plasma Unit

Plasmatreat OPENAIRTM Plasma System

- Plasma generation system

- Nozzles: 0, 14, 45 degree openings

- Primary interest: Preparing composite surfaces for bonding

- Work area of 510 x 510 mm (20.07 x 20.07 inches)

- Repeatability of 0.01 mm

- Teach pendant or PC programming

Curing Oven

Despatch LAC1-67 Oven with vacuum pass-through

- Temperature range: 40 to 260 °C (104 to 500 °F)

- Chamber size: 61 x 50 x 62 cm (24 x 20 x 24 inch)

- Temperature uniformity at 260 °C: ± 2.5 °C (±4.5 °F)

- 5 cfm free air displacement